Relief Well Maintenance

Posted on Wednesday, October 19th, 2016 by Affinis CorpIn Structural, tagged in Tags: dams, levees, maintenance, relief wells, usace

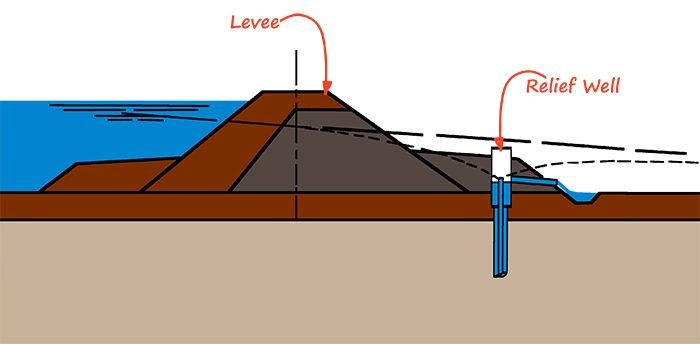

Relief wells are constructed to provide pressure relief caused by floodwaters at the landward toe of the levee. Excessive pressure at the landward toe of a levee can cause sand boils to develop. When this occurs, levee material moves (called piping). If enough material is piped from the foundation, a direct path can be created, allowing floodwaters to flow directly into the protected area, or it can cause the levee to subside and floodwaters to overtop the levee triggering failure. Relief wells are typically only used where there is not enough right-of-way or other restrictions (such as buildings) to construct an underseepage berm on the landside toe. The berm works by pushing those pressures further landward until they are dissipated to safe levels.

A relief well is composed of two primary components. These include a stainless-steel screen and filter pack (placed outside the screen). The screen is sized to allow water to pass through, but not the filter pack. The filter pack is composed of a graded granular material that is sized to let water to pass through, but not the surrounding aquifer soil. Think of these two items as filters that keep the surrounding aquifer material from being piped and provide pressure relief by allowing water to flow.

Relief wells require routine maintenance to remain operational. Their functionality is measured against their original specific capacity. In fact, wells must maintain 80 percent of the original specific capacity to be considered acceptable by U.S. Army Corps of Engineers’ (USACE) standards.

The original specific capacity is determined in the final steps of the relief well installation, during pump testing. The original specific capacity sets the baseline for routine, follow-up pump testing that is conducted every five years. A reduced specific capacity is an indicator of a plugged or underperforming well.

Relief wells go through a life cycle in which they maintain their pump capacity for a while, then enter a slow decline, and finally, lose capacity exponentially as they approach the end. In general, relief wells start the slow decline around year five. The reason for this decline is the continual growth of the carbonate in the filter pack.

To clean a relief well, there a few steps you can take:

- Bail out the well to remove debris or sand from the bottom of it.

- Brush the well screen to remove encrustation and open the screen to the filter pack (gravel) around the relief well.

- Perform a chemical dosing. On a recent Downtown Airport project, we used acid. The acid dissolves the calcium and magnesium carbonate to remove the encrustation that is blocking the relief well from flowing.

- Then, surge the well to push the chemical dosing into the filter pack. Surging is done with a swab that acts as a giant piston to push the chemical out and suck the dissolved carbonate in for removal.

- Neutralize the acid, bail the well, and pump out the chemical dosing.

- Finally, pump test the well to determine capacity

Cleaning the well becomes more difficult based on the amount of encrustation that has built up in the filter pack. It becomes more challenging, because it is harder to get the chemical out far enough into the filter pack to dissolve the encrustation. This is why it is critical to pump test relief wells routinely. It helps clean the well, while the filter pack is relatively free of encrustation.

You can measure whether or not a well can be restored (versus having to be replaced) by looking at the general percent of specific capacity of the original specific capacity.

- 85 percent or greater: Full capacity can be restored.

- 85 to 60 percent: Full recovery is possible.

- Less than 60 percent: Full recovery is not likely.

- Less than 40 percent: The well may be unsalvageable.

USACE requires that relief wells are pump tested every five years. This ensures those requiring cleaning can be discovered early, so they can be brought back up to functional levels. We recently performed testing for USACE on the Downtown Airport. While we were able to bring many of the wells back online, some are being replaced, as they’ve reached the end of their design life.